A Short Introduction to Nanotechnology Normalization in Poland and in the World

Currently, nanotechnology is the most rapidly developing interdisciplinary branch of science, which presents an opportunity to bring engineering to an entirely new level, allowing for impressive results for the economy in the nearest future. This technology is revolutionary for practically every branch of the industry. In the European Union, nanotechnology is considered a Key Enabling Technology (KET) of the 21st century. Manufactured nanomaterials (MNMs) have found a number of applications in electronics, construction, energetics, transportation, chemical, automotive, and textile industries, telecommunications, cosmetics, as well as medicine, environmental protection, agriculture, food and other industries.

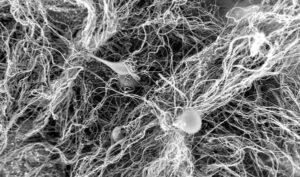

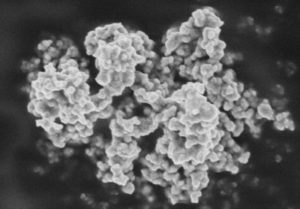

That leads inevitably into taking steps towards normalization and standardization of nanofabrication standards. European Normalization Committee (CEN, z fr. Comité Européen de Normalisation) and International Organization for Standardization (ISO), in ISO/TS 80004-1:2015 document (Nanotechnologies — Vocabulary — Part 1: Core terms), define a nanomaterial as ‘a material with any external dimension in the nanoscale or having internal structure or surface structure in the nanoscale’, where nanoscale is defined as the size range from approximately 1 to 100 nm. Generic term ‘nanomaterial’ is inclusive of ‘nano-object’ and ‘nanostructured material’. That would be the first step.

There is a great effort of numerous institutions put into standardizing nano-connected industries, but often not even nanotechnology specialized scientists or entrepreneurs are aware of them. As NanoFabNet project aims to connect all the stakeholders with this article we would like to introduce this important topic to those that are not familiar with it, so that we can build our awareness of this topic together in the course of the development of the NanoFabNet Hub community.

Why should we normalize materials?

As mentioned earlier, nanotechnology is one of 6 KETs that have the greatest impact on the EU prosperity and competitiveness, having great impact on various industries. The use of MNMs is more and more popular in the workplaces and our everyday environment, including in consumer goods. Despite many advantages, scientist prove nanoparticles might also cause some negative health consequences when absorbed through nose nerve, lungs, skin or eyes. The other thing is probability of such an event, toxicity evaluation of certain substances and other risks. That is why there is a great need to investigate and gather data on how interaction with nanoparticles impacts our live and to see the potential scale of damages.

To appropriately test, investigate and produce nanomaterials, we need validated and normalized methods.

Who normalizes nanomaterials?

The norms and recommendations on nanotechnology and nanomaterials are created by numerous groups around the world – both national and international, inspired by local governments or nongovernmental institutions.

To the most important organizations that lead in establishing (voluntary in implementation) norms connected to nanotechnology are:

- International Standardisation Organization (ISO), with two technical committees: ISO/TC 229 – Nanotechnologies and ISO/TC 146/SC2 – Workplace atmospheres,

- European Committee for Standardization (CEN, French: Comité Européen de Normalisation), with technical committees: CEN/TC 352 – Nanotechnologies and CEN/TC 137 – Assessment of workplace exposure to chemical and biological agents.

- American Society for Testing and Materials (ASTM), where Committee E56 on Nanotechnology works since 2005

- International Electrotechnical Commission (IEC), where we have a technical committee TC 113 – Nanotechnology standardization for electrical and electronic products and systems.

- Institute of Electrical and Electronics Engineers (IEEE), where Nanotechnology Council was initiated.

Some more of the active insitutions in this field are: :

- British Standards Institution (BSI)

- Institute for Reference Materials and Measurements (IRMM) with headquarters in Geel, Belgium – one of the six scientific sites of the European Commission’s Joint Research Centre (JRC).

- Organization for Economic Co-operation and Development (OECD) with working groups: Working Party on Nanotechnology (WPN) and Working Party on Manufactured Nanomaterials (WPMN). Since 2005 OECD have published series of reports, guidelines and recommendations in the cycle: “Series on the Safety of Manufactured Nanomaterials”. Documents are available here: >>CLICK<<.

Nanotechnologies are also in the scope of priority research in the World Health Organization (WHO) agenda. A worth-reading WHO document that describes general safety recommendations for work with nanomaterials is Guidelines on protecting workers from potential risks of manufactured nanomaterials” from 2017.

What is the EU nanomaterials normalization approach?

In 2004 EU funded Scientific Committee on Emerging and Newly Identified Health Risks (SCENIHR) in order to evaluate the risk coming with nanomaterials. European Union is still working on the nanomaterials definitions, that will affect safety measures.

Currently Commission Regulation (EU) 2018/1881 of 3 December 2018 amending Regulation (EC) No 1907/2006 of the European Parliament and of the Council on the Registration, Evaluation, Authorisation and Restriction of Chemicals (so called REACH) introduced the term nanoform with what it obliged companies that produce and introduce nanomaterials to the market to follow the rules on registration, evaluation, granting permissions and limitations with regard to chemicals. Regulation 2018/1881 also introduces the obligation to conduct a health risk assessment of substance nanoforms. The regulation has been in force since January 1, 2020. According to the REACH regulation and the supplementing CLP regulation (Classification, Labeling and Packaging), nanomaterials are subject to appropriate classification, labeling and packaging. CLP Regulation stipulates that all substances in the nanoform must be labelled according to the CLP criteria in order to convey information concerning hazards linked to particular nanomaterials. Nanomaterials placed on the market (manufactured or imported above 1 tonne per year) must undergo the registration process with the European Chemicals Agency in Helsinki (ECHA). Increased safety control is carried out in relation to cosmetic, biocidal and food products. Besides, the relevant additional activities (information, preparation of safety data sheets, exposure scenarios, etc.) depend on the tonnage of production.

What is going on in nanomaterials normalization in Poland?

In Poland where NANONET Foundation originates, the normalisation is given a closer look by the Polish Normalisation Committee (PKN, Polish: Polski Komitet Normalizacyjny). W Polsce sprawami normalizacji zajmuje się Polski Komitet Normalizacyjny (PKN). The subject of nanotechnology is the responsibility of the Technical Committee 314, whose main task is to harmonize national and European standards in close cooperation with CEN / TC 352 and ISO / TC 229. The employees of the Nanonet Foundation are active members of the Technical Committee 314 for nanotechnology at PKN.

Stakeholders in standardization can be: community organizations, producers, service providers, academia and education, public authorities and consumers. The benefits of standardization and active participation in its work (quoting from PKN materials) are:

“Constant access to documentation and draft standards, direct impact on the content of standards, reduction of design and research costs, gaining competitive advantage and the possibility of planning investments thanks to knowledge of current standardization works, ensuring compliance with European and international standards, consistency of technical solutions, facilitating trade international, ensuring the protection of the life, health and environment of consumers and occupational health and safety.”

Stakeholders can influence the content of the standard by (quoting also from PKN): ”Proposing new topics or issues, participation of an expert in the working group, determining the difference between the CEN draft and the provisions of Polish law (reporting national deviations from the draft European standard), reporting comments to the standard draft,, raising objections to the finished document (in the event of non-compliance with the law European Commission)”

Obviously there are many different models of cooperation in this fields in every country. That is why we believe creating a community of experts aware of those issues might be beneficial for the development of the sustainable nanofabrication good practices and standards based on knowledge exchange.

If you have a broader experience with validation, harmonisation and standardization issues in sustainable nanofabrication already, we would strongly encourage you to share it with us by filling in our survey:

http://nanofabnet.acumenist.com/contact-nanofabnet/#validation-survey

Authors: NANONET Editorial Team, NANONET Foundation

References:

“Bezpieczeństwo stosowania, przetwarzania i produkowania nanomateriałów”, Bezpieczeństwo Pracy. Nauka i Praktyka; 2019-03-01

Krótki przewodnik po normalizacji nanomateriałów w Polsce i na świecie

https://wiedza.pkn.pl/web/wiedza-normalizacyjna/nanotechnologia